Irene Byon, a tourist customer at a local design studio in Copenhagen, Denmark, walks through the aisles of ceramics, enraptured by the colors and textures around her.

“I like that everything’s handmade and has unique designs to it,” Byon said.

Like Byon, many people are appreciative of the craftsmanship and creativity involved in the creation of ceramics. However, fewer are aware of the strides this niche art form is making in the world of sustainability.

Why It’s Newsworthy: In Denmark, a country known for its art and design, it’s no surprise that ceramics production has been on the rise. However, this creates a new problem that the country is working hard to solve: how to make this art form sustainable.Nina Husted Erichsen, the head of the program for crafts in glass and ceramics at the Royal Danish Academy of Fine Arts, says worldwide interest in ceramics has been resurrected within the past decade, attracting more buyers and encouraging the opening of countless ceramics studios.

This can especially be seen in Copenhagen, Denmark, where more craftspeople have been able to study ceramics at dedicated schools like the Royal Danish Academy and go on to start their own businesses.

Unfortunately, behind these delicate creations lies a myriad of environmental issues. Erichsen explained that clay, one of the most important materials for ceramics, often has to be transported across great distances, creating large amounts of pollution along with depleting these natural reserves. Because a lot of clay is left over in the process of casting, shaping and trimming ceramic pieces, clay wastage is also a common problem in ceramics studios.

Furthermore, ceramics production requires very high energy consumption. Sussi Krull, the owner and designer of a local ceramics studio called Wauw Design, said her kilns have to be fired twice at temperatures as high as 1,300 degrees Celsius to glaze a single piece: it is difficult to justify using energy levels per firing that are sufficient to run a small household.

What Is Being Done

Many local ceramics studios in Copenhagen have recognized these issues in their craft, and are now finding innovative strategies to address them.

The largest of these strategies is recycling clay, where instead of disposing of the small amounts of clay left from the pottery process, ceramicists are collecting this surplus and finding ways to recycle and reuse it in future pieces.

At Wauw Design, ceramicist Sussi Krull has been recycling her clay since 2009 and using it in the pieces she creates for her ‘Sustainable Collection.’

“I have so much leftover clay, so I have to try and use it some way,” said Krull. “I think it would be ridiculous to throw it out.”

However, recycling clay is no simple process: it involves multiple steps and variations based on the type of piece being created, and while there are many ways to do it, Krull follows her own curated method, which involves minimal equipment.

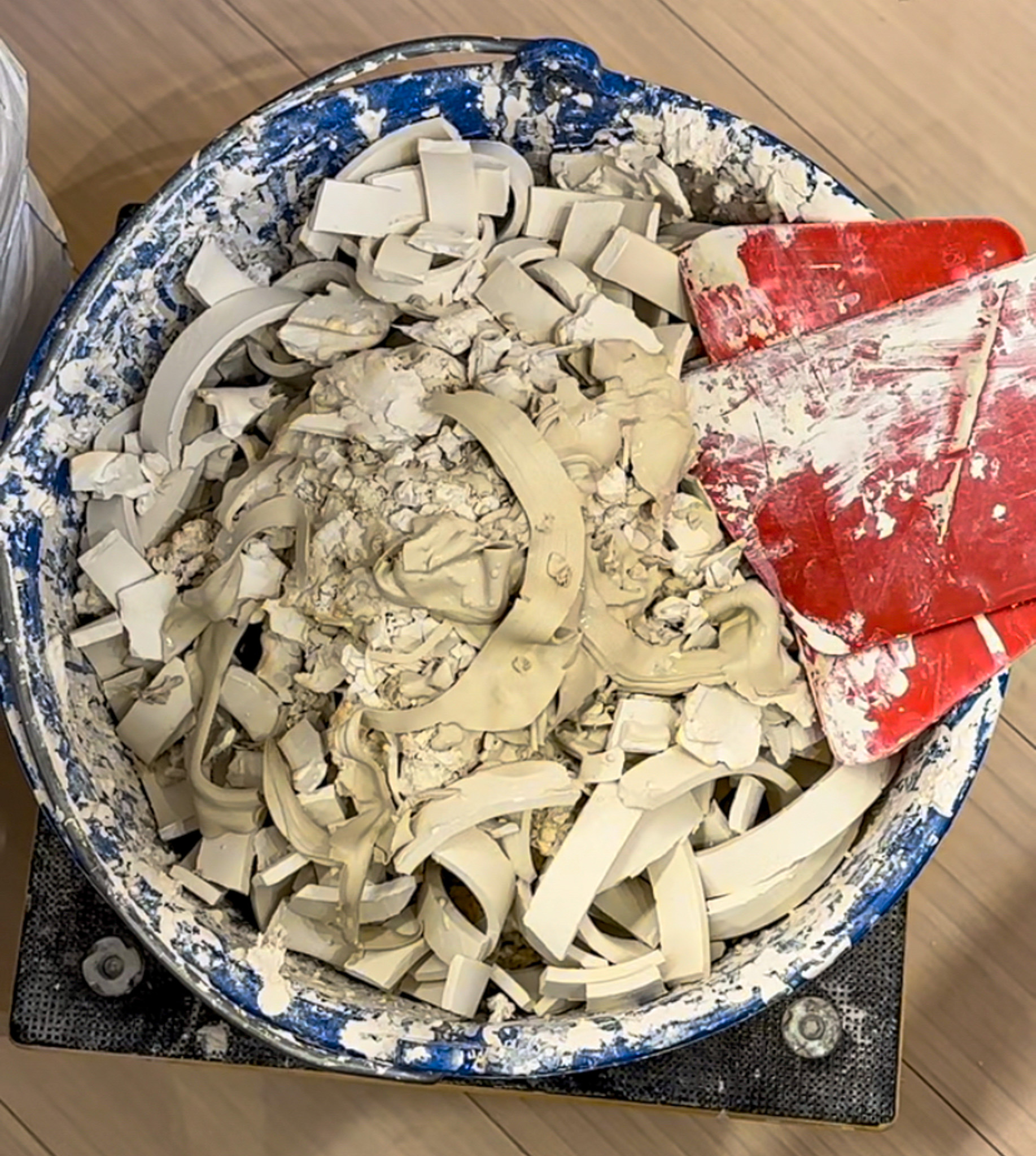

First, Krull collects any surplus clay in large buckets, which she then puts out to dry completely: a process that can last from days to weeks.

After this, she does one of two things. For the clay she plans to use for slip casting — a special ceramic-forming technique where a clay solution is poured into plaster moulds — she breaks the now hardened clay into small pieces before mixing it thoroughly with water and a special chemical called Dispex, creating a milky consistency which can then be poured into moulds after being allowed to settle.

Here is a video of the process of recycling slip cast clay:

For the clay she plans to work with her hands, Krull simply soaks the fully dried recycled clay in water and lets it set to a more solid consistency, which can be thrown on a potter’s wheel.

Either way, what Krull ends up with are unique porcelain vases that are never the exact same, building a collection of ceramics which are beautiful, functional, and most important, a sustainable product.

However, sustainability in ceramics doesn’t just end at recycling: it also comes down to the sourcing of its raw materials and how far they have to travel before they reach a studio.

Over the past few years, there has been a movement of looking for “wild clay,” says Erichsen. Instead of relying on distant mines which may be depleting, more ceramicists have begun finding local sources and even looking at their own surroundings for raw materials, Erichsen said.

One ceramics studio in particular, Studio Arhoj, has found an especially unique local source for some of its creations: old bricks.

Denmark is ridden with traditional brick buildings which are beginning to crumble and decay. For their collection titled “The Brick Project,” Studio Arhoj has started collecting these bricks — which are nothing but pieces of fired clay — and glazing them to create new ceramic pieces.

Not only does this give the studio a local source for their creations, but it also significantly cuts down energy expenditure by reducing how much time this already-fired clay spends in a kiln.

While this may not be a mainstream practice, Studio Arhoj’s brick project contributes to a larger trend of reusing and upcycling existing materials to push the tradition of ceramic creation in a more sustainable direction.

“Every little thing you can do, every knob you can turn and make it a little better, you should do,” said Anders Arhoj, founder and designer of Studio Arhoj, about the need for sustainable practices. “That is why we’re doing it.”

The efforts of Copenhagen’s local ceramic studios do not end here: from using clean energy sources for their kilns to wrapping their ceramics in recyclable packaging, causing minimal harm to the environment remains ingrained in every aspect of their business.

The Future

In spite of these efforts, some aspects of the ceramics industry remain unsustainable. Erichsen explained that with every firing, kilns will continue to expend enormous amounts of energy, and perhaps most importantly, the firing process cannot be reversed: once a ceramic is made, it is very difficult to deconstruct and can take thousands of years to decompose.

For this reason, a sustainable solution may lie not just in the creation of ceramics, but also in the public’s use of them. Contemporary ceramic pieces make beautiful showpieces, but they are also durable enough to last for lifetimes, and if used as such, they even have the potential to replace harmful materials like plastic.

As ceramic production continues to increase worldwide, both its sellers and consumers will play a role in making it a truly sustainable craft.

Navya Shukla is a junior majoring in journalism and psychology at the University of Georgia.

Show Comments (1)