The streets of downtown Athens fill with music lovers as the weekend begins. It is no secret that Athens is a hub for live music; however, many people don’t realize that the only vinyl record pressing plant in Georgia is just a few minutes up the road. In this factory, with dark blonde hair over his eyes, tight jeans, and his skate shoes, sits Daniel Geller, one of the owners of Kindercore Vinyl.

Daniel Geller is a person who combines his passion for music with his biological and agricultural engineering background to find more eco-friendly ways to produce the plastic that makes vinyl records. With Kindercore Vinyl being the only pressing plant in the state, it opens up a door to find a large customer base and the ability to form a unique reputation of eco-friendliness.

Geller is currently researching ways to produce or purchase a petroleum-free plastic to press the records in order to reduce Kindercore’s impact on the environment. Geller is a “Triple-Dawg,” meaning he got his bachelor’s, master’s and doctorate degrees from the University of Georgia. His doctorate is in biological and agricultural engineering, where he focuses on renewable energy and bio-fuels. Geller and his colleagues at Kindercore strive to innovate new ways to protect the environment through their production.

“One of the main goals of Kindercore is to be the ‘eco-friendly vinyl company,’” Geller said. “That was my main project when I started Kindercore, was to develop that new vinyl replacement.”

Why It’s Newsworthy: Athens is well-known for its music industry, providing the opportunity to record, produce, and perform music all within the city. As the only pressing plant in Georgia, Kindercore Vinyl is working to produce an eco-friendly plastic to produce vinyl records in order to lessen their impact on the environment.

Music has always been a part of Geller’s life, as he has been in multiple bands, toured internationally, and now produces vinyl for retail sale.

From Wisconsin to Georgia

Growing up in Waukesha, Wisconsin, Geller found himself hanging with various social groups and trying to get involved with music. Mark Mallman, Geller’s hometown best friend, describes Geller as being part of the skater crowd. Mallman was sort of an outcast in school but became friends with Geller once he discovered their mutual love for music. They would talk music and share each other’s creative content with constructive critiques. When high school ended, Geller and Mallman parted ways, as Mallman moved to Minnespolis and Geller moved to Athens; however, they kept in touch throughout college and still today.

Geller was in search of the college life that is seen in movies, full of socialites and non-stop fun. He had visited Georgia Tech but didn’t really feel like he would be a good fit there, as he was looking for something different. Geller decided to also visit UGA while he was in the state.

“I literally stepped out of the car, we had parked in front of O-House, and it was almost electric when I put my foot down,” Geller said. “I know it sounds stupid, but the minute I stepped foot in Athens, I was like ‘woah, this is my home.’ It was a really weird feeling.”

Geller soon moved to Athens and started mingling with people in the music scene.

Birth of Kindercore

While completing his undergraduate degree, Geller met his current business partner, Ryan Lewis. As Geller continued his education for his master’s degree, the two started a band called Kincaid. Geller and Lewis initially created Kindercore as a record label so that they could release Kincaid’s music. Geller explains that once they released the music for Kincaid, that other groups came to them to release their music as well, growing the label. Geller and Lewis began touring with their band and had to hire another company to run the label for them while they were in Europe on tour.

Since it was the early 2000s, there were not many reliable communication options, and according to Geller, international phone lines were very expensive at the time. This lack of communication opened the door for the hired company to partake in risky and sneaky business practices, syphoning money out of the account of Kindercore and into their account. Once they returned from Europe, Geller and Lewis had essentially lost all of their money and were back to square one with the Kindercore record label. These illegal business practices led to a very expensive lawsuit with the hired company that, according to Geller, drained him of his life savings at the time. With the record label on hiatus, Geller decided to dive more into his academic research, working full-time in a laboratory at UGA to do research into bio-fuels and renewable energy.

Academic Pursuits in Innovation

Pursuing his doctorate, Geller became a faculty member of UGA’s Innovation Gateway program, which strives to assist inventors in commercializing their ideas and products. Ian Biggs is the senior associate director of the startup program, and with his soft English accent, he explains that they brought Geller in because he had experience with startups. Biggs felt that Geller had knowledge that he could pass on within the program, given that Geller has seen both success and failure in startups.

Biggs explains that when the two first met, Geller told him about his experiences with his businesses. This field is full of trial and error, and requires lots of creativity, often times bouncing ideas around to other people to find solutions to problems. “The things that he’s been through, starting his businesses and the search for money, things like that, he’s proved himself to be very resilient,” Biggs said. Geller feels that this program has allowed him to grow and has given him the ability to bring this knowledge to the music industry.

Return of the Vinyl Record

In 2016, Ryan Lewis and his business partner approached Geller with the idea of resurrecting Kindercore, but instead of continuing the company as a record label, they wanted to become a company that actually presses the vinyl records. Geller explains that Lewis and his partner could have just paid a fee to license the name and left him out of the company, but they wanted to work with him.

“I think the real reason they wanted me to be a part of the business itself, was to bring that Ph.D. with me and the clout that it brings and the people that I know,” Geller said. With vinyl records making an unexpected comeback, they felt that they could be successful in pressing vinyl records.

The purchase of vinyl records has seen a steady increase in the last decade. The Recording Industry Association of America (RIAA) is in charge of the creative and financial vitality of music companies in the United States, tracking sales of music on all platforms, physical and digital. According to the RIAA U.S. Sales Database, vinyl sales saw $497.6 million in revenue in 2019, an increase of 459% from 2010. This resurgence of vinyl has allowed Kindercore to succeed as the only pressing plant in Georgia and cement themselves as a major competitor in vinyl production in the Southeast.

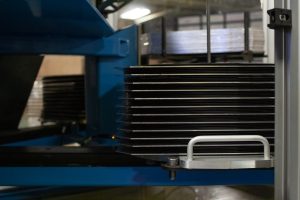

Ryan Lewis runs the production side of Kindercore Vinyl, where automated machines press thousands of records every day. Lewis explains that he believes this resurgence of vinyl happened because people enjoy having physical copies of music. Lewis also states that with the physically large size of the record, bands are able to provide more detailed information about the album on the packaging, allowing their fans to know more about who was involved with the album’s production.

As the head of the record manufacturing process, Lewis seems to be constantly coming up with big ideas to move the business forward.

“I’ve always been sort of the big idea person, who comes up with some crazy idea and then tries to get Dan to go along with it,” Lewis said. “You know, he’s always been really good about trying to grab my ideas and make them real.”

Lewis credits Geller with being an integral part of pitching the idea of Kindercore Vinyl to investors, while trying to obtain and organize financial aspects, in order for the business to begin and prosper.

Now in their third year of vinyl record production, Kindercore Vinyl has pressed over a half million records. During the current COVID-19 outbreak, Kindercore Vinyl is one of the very few pressing plants still open. Geller explains that they are taking many steps to stay open, while maintaining the good health of their employees and clients. They have been working two shifts, as well as maintaining social distancing practices and sanitizing the factory on a daily basis. To Geller’s surprise, their production has not seen a negative impact from the virus outbreak.

Eco-Friendly Vinyl Replacement

Striving to lessen their impact on the environment, Geller is researching ways to obtain or produce petroleum-free plastic to press the vinyl records. Geller initially used his own lab to do the research but quickly discovered that he had limited resources, so he decided to reach out to the New Materials Institute at UGA and began working with them to find an eco-friendlier vinyl replacement.

While also using his connections in UGA’s Innovation Gateway program, Geller has discovered the difficulties that come with finding a vinyl replacement.

“There are two challenges when it comes to making vinyl,” Geller said. “One is that the physical properties of the vinyl are specific, and it’s been very difficult to find a biologically based replacement that works.”

Geller explains that he has found people who have made a plastic they believe will work, but this is where he faces the second problem. Although vinyl sales are increasing, when it comes to overall plastic production, they are just a drop in the bucket.

To solve this problem, Geller is looking to increase the demand of this eco-friendly plastic by partnering with companies who are also willing to use the plastic because the company that produces the plastic would not survive financially if their only customer is Kindercore.

“If we can get to a certain volume, which is huge, it’s like 100 times what we make now,” Geller said. “If we can get to that demand, there’s definitely potential for that to happen.”

Geller credits a lot of this success to his network within the University and the music industry. While the demand is still low, Geller is positive that they will reach the right level of demand in the future.

Expanding Business, Furthering Innovation

Geller looks to continue pursuing a career in both music and academia. He explains that he will continue to be a part of the Innovation Gateway program, and still has two more years of grants in the UGA College of Engineering that are funding his research on bio-fuels and antibiotics. Over the course of those two years, Geller plans to transition completely over to the Innovation Gateway.

“That is where I see my career going now. I’m going to be working to help other people commercialize their ideas,” Geller said. “Because I have this unique combination of experience in industry and experience in academics and having successes and failures…[that has] kind of pushed my career in this direction.”

Geller’s group is also wanting to branch out to the creative arts, so he will help art, music, design, and dance students to commercialize their ideas.

Geller has seen success and failure in business, showing great resilience through the hard times. He wants to pass this knowledge on to the next generation of inventors in hopes of commercializing their ideas. Geller believes that Kindercore has finally turned the corner to be a profitable business and feels that they will always have a place in the industry, due to their quality assurance and eco-friendly reputation. Kindercore’s clientele continues to grow because when the client places the order, they know they are going to get a quality product.

Will Broadwater is a senior majoring in journalism and pursuing a Music Business Certificate at the University of Georgia.

Show Comments (0)